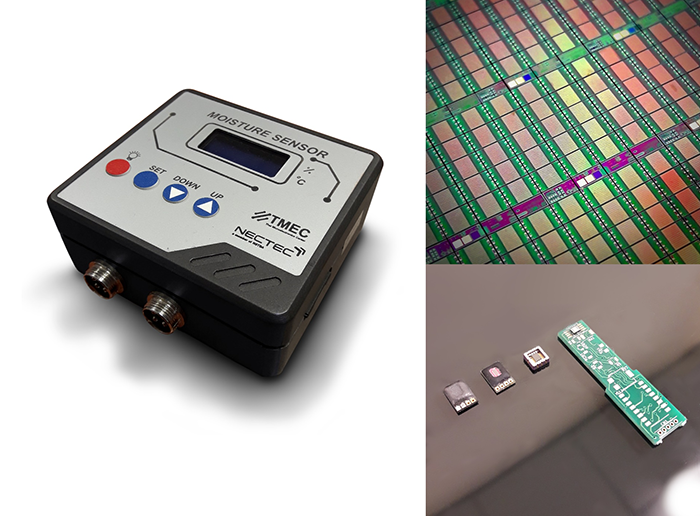

Silicon Industrial Fabrication Research team (SIFRT) is a team under Thai Microelectronics Center (TMEC), Our research team has developed both local and international research collaboration and connections with research units, academics, institutions and etc. For example, a joint research project to develop a silicon microchannel heat exchanger between TMEC-ALICE/CERN, a customization fabrication process and services of silicon mold for private companies and etc. SIFRT consists of 3 research groups as follows:

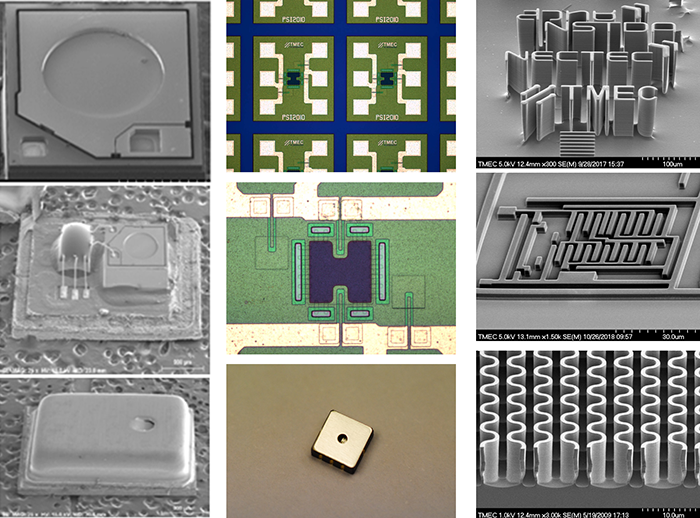

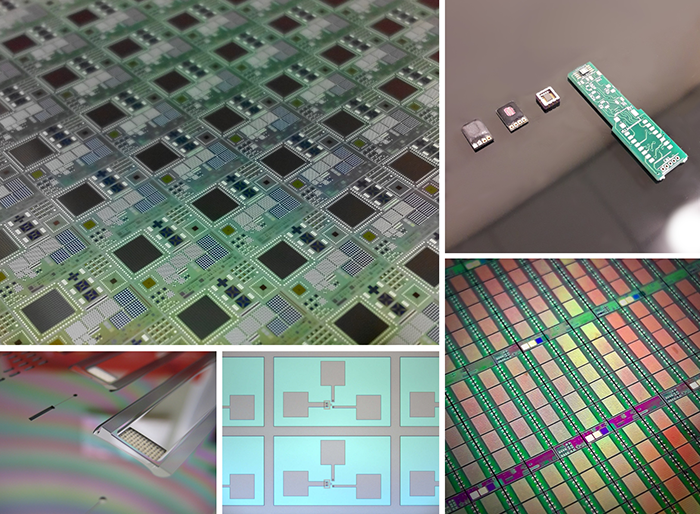

- Silicon Process Technology Team (SPT): A research group with knowledge, skills, expertise in CMOS-MEMS microfabrication technologies including hand-on experiences in operating various machines and tools in the cleanroom.

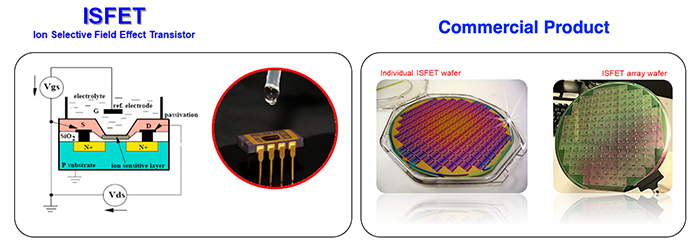

- ISFET Team (IST): A research group with knowledge, skills, expertise in Ion sensitive field effect transistor (or ISFET) technology that is used as a platform for developing chemical sensors and biosensors.

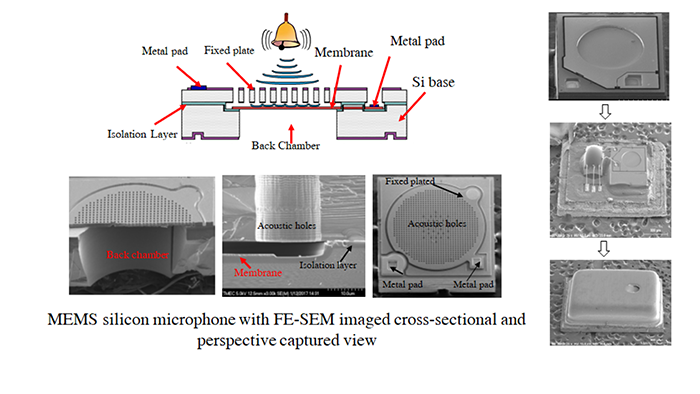

- MEMS Team: A Research groups with knowledge, skills, and expertise in design, simulation modeling and fabrication of various micro-devices and micro-structures using CMOS-MEMS fabrication technologies This also includes post-fabrication process such as assembly, packaging, electrical properties and functional testing, product reliability and qualification of sensors and MEMS from concept to prototype to commercial products.

สารบัญ

Vision

To promote and support the study, research and development, technology transfer and applications related to Si CMOS-MEMS fabrication technologies of various sensors and MEMS devices including other microdevices and microstructures that pave the way to development of new technologies and innovations in the future. Aiming towards the ultimate goal is to create a concrete upstream microelectronics industry in Thailand, and to demonstrate competitive advantages.

Mission

- Research and development of both optimal and advanced sensors, MEMS, microdevices, and microstructures onto silicon substrates using CMOS-MEMS fabrication technologies

- Research and development of Ion sensitive field-effect transistor (or ISFET) technology as a platform of chemical sensors and biosensors

- Enabling the ecosystem of advanced sensors and MEMS production in Thailand

Core Technology

- CMOS-MEMS fabrication technologies for sensors, MEMS, microdevices and microstructures onto silicon substrates

- ISFET or Ion sensitive field technology transistor is a platform for developing chemical sensor and biosensors, with ISFET surface modification that are specific to the substances needed to measure on the silicon nitride layer which is an ISFET gate dielectric. For example, development of ISFET-based sensors comprises of nitrate sensor, DNAA sensor, DNA biosensor and TB sensor.

Renown Project

- Development of photonic array biosensor technology and ISFET-based sensors for detection of fungal toxins [2019-present]

- The prototype “Handheld Real time ISFET based nitrate” has been awarded the Silver Medal Award from 2017 Taipei International Invention Show & Technomart Invention Contest, which is held at Taipei World Trade Center between 28-30 September 2560 in Taipei, Taiwan

- A silicon nitride ISFET based immunosensor for Ag85B detection of tuberculosis [2016]

- Non-enzymatic urea sensor using molecularly imprinted polymers surface modified based-on ion-sensitive field effect transistor (ISFET) [2016]

- Prototype development of durable nitrate sensor by surface modification [2016-present]

- Development of an immunoFET biosensor for the detection of biotinylated PCR Product [2016-present]

- Prototype development of piezoresistive pressure sensors using the integrated CMOS-MEMS microfabrication on the silicon sub-state. The pressure rage is 0-30 bar enabling them to be potentially applied in different areas such as in agriculture, industrial, medical etc., and higher pressure range up to 50 bar for specific application in the near future. [2014-present]

- Developed the manufacturing process of the probe for use with the pressure wire in the heart of the product, RADI Medical Systems AB, Sweden (currently merged with Saint Jude Medical in the United States) to assist in the measurement of blood pressure for patients with coronary artery disease. By developing commercial prototypes of blood pressure sensor was 120,000 dies (the 1st generation) to 400,000 dies (the 5th generation) [2004-2013]

- Development of fabrication process for the first generation Si MEMS microphone having a diaphragm that detects sound pressures (acoustic waves), made of an epitaxially grown silicon. In the second generation, a diaphragm is constructed from a thin-film polysilicon [2015-present]

- Development of fabrication process for the first generation of high-precision MEMS gyroscope prototype. [2019–present, in a process of developing a proposal with the start-up company]

Members & Expertise

I. Silicon Process Technology Team (SPT)

- Mr. Jakrapong Supadech (Leader) : MEMS microphone, pressure sensor gyroscope, CMOS-MEMS process integration, plasma etching (RIE, ICP & Si DRIE)

- Mr. Nimit Somwang : Ion-implantation, wet chemical etching

- Miss Rattanawan Meananeatra : Photolithography, mask design, layout and tape-out

- Mr. Arckom Srihapat : Plasma enhanced chemical vapor deposition (PECVD), 3D-printing design and modeling

- Mr. Aekchai Chummano : Wet chemical etching, wafer cleaning

II. ISFET Team (IST)

- Mr. Win Bunjongpru (Leader) : ISFET platform for chemical and biological applications, CMOS-MEMS process Integration, sputtering

- Mr. Woraphan Chaisriratanakul : Polymer sensing membrane technologies

- Mr. Awirut Srisuwan : Planar solid state reference electrode, plasma etching (RIE)

- Mr. Apirak Pankiew : Quality control of ISFET devices, Photolithography and wet chemical etching

- Mr. Nutthaphat Thornyanadacha : Advanced integrated circuits (ICs), sensors and MEMS packaging technologies

- Mr. Somkiad kaewno : Sputtering

- Miss Panyasiri tadaworawit : Plasma etching (RIE)

III. MEMS Team (MEMST)

- Miss Hwanjit Rattanasonti (Leader) : MEMS microphone, pressure sensor, gyroscope, micro-energy harvesting devices (e.g., thermal, vibration), microfabrication ion traps, CMOS-MEMS fabrication process, device characterization and failure analysis

- Mr. Putapon Pengpad : A CMOS-MEMS humidity sensor integrated with micro heater, a graphene-based humidity sensor for linearity improvement of sensing curves, MEMS pressure sensors, rapid thermal processing (RTP)

- Mr. Karoon Saejok : MEMS pressure sensor, Ion-implantation

- Mr. Ekalak Chaowicharat : MEMS microphone, pressure sensor, gyroscope, accelerometer, CMOS-MEMS fabrication process

- Mr. Chana Leepattarapongpan : MEMS microphone, pressure sensor, magnetic sensor, wet/dry oxidation and thin-film deposition

- Mr. Watcharapong Paosangthong : Photolithography, energy harvesting technology (*on study abroad)

Contact

Thai Microelectronics Center (TMEC)

51/4 Moo 1 Suwintawong Road, Wangtakien,

Muang, Chachoengsao 24000, THAILAND

Tel: +66 (0)38-857-100 ext. 0

Fax: +66 (0)38-857-175